Manufacturing Process For

COPPER & COPPER BASE ALLOY PRODUCTS

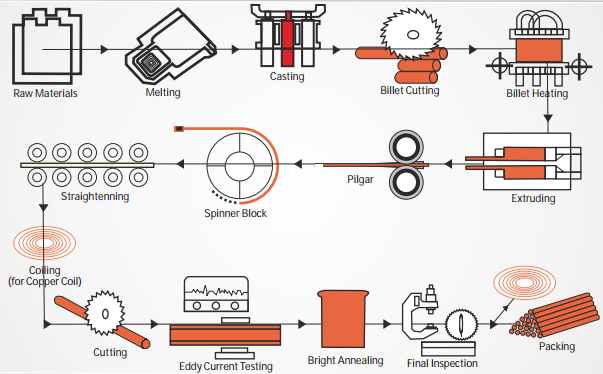

At Mercure highly advanced technological processes are used to manufactor product which involve melting in introduction furnaces, Extrusion by 1600 metric tonne oil hydraulic extrusion press, Cold drawing by pilger mills, sophisticated drawbenches & modern bull blocks, intermediate process annealing by gas fired furnaces, Final annealing by bright annealing furnaces, Straightening & colling process, & final inspection & testing. Incoming Raw Material is tested in laboratory and then issued to melting shop. This material is molten cast in watercooled molds. The cast logs are cut into billest of suitable length.

These billest are pre-heated to proper extursion temperature and extruded into mother Tube/ Road/ Section undergo pickling if required. Then undergo pointing, cold drawing and if required intermediate anneling. The Tubes, Road, Section are straightened. Tubes undergo Eddy current testing/ Hydrostatic testing. The product undergo annealing if customer require them in soft temper or draw further if required Half hard/Hrad Temper. The finished products undergo visual check, Dimensional check, Flaring, Flattening test, physical properties, and grain size test are also carried out before packing and despatch.